|

Previous Builder

Next Builder

Date: 08-16-2024

|

Number of Hours: 40.00

|

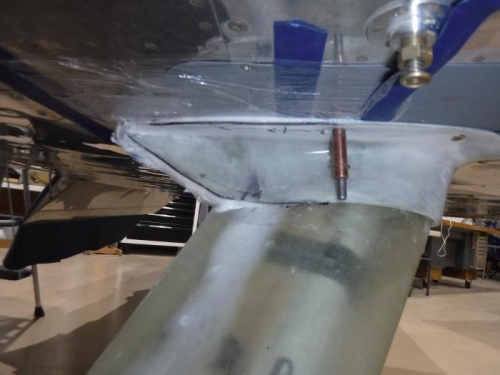

Short Description: Fiberglass Fairings Final Prep-Work

|

There is an incredible amount of final preparation to get the final fiberglass firings ready for priming. Many of the parts still did not fit together the way I wanted them to. There were gaps on the upper and lower main gear fairings and the aft-ends still did not close together. It’s very frustrating and the more I more on them, it seems like I get one part to fit correctly but the additional amounts of flox, epoxy, and microbeads tends to distort another part. I’ll work on these two more weeks, then it will be what it will be until I have flown the airplane a few hundred hours and am ready to paint. In the meantime, I will do as much as I can to get the beast ready for inspection and certification.

Floxing Upper Main Gear Fairings

|

Trying to Fill Gaps & Close Aft-End

|

Same Issues with Lower Fairings

|

Previous Builder

Next Builder

|