|

|

|

|

RV-6A - GBC

|

Date: 2-8-2008

|

Number of Hours: 10.00

|

Manual Reference: Dwg #35

|

Brief Description: Instrument panel, fitting

|

|

Long day, more pics on next entry. At the end of the day, I'm satisfied with the result. Started with a panel that was roughed in, very rough. Ended with a panel that was fit to dimensions and solid.

Months ago, I rough cut the shape and 'slots' for the F-603, instrument panel. Wasn't happy with it and worked on my skills elsewhere. After reviewing many websites and builder panels, several design techniques emerged. I decided to mount the vents independent of the panel, and use the faceplate as a 'mask' to cover the poorly cut slot gap, too. This also allows raising the bottom of the panel slightly to reshape the top edge for best fit. This makes a 'bottom edge' subpanel for switches more viable.

The F-645 panel braces are mounted higher than spec, but can be lowered if required when I get the finishing kit. Looking ahead at the RV-6A plans for tip-up canopy, there doesn't appear to be an interference.

Started working on the angle for the top edge. See next entry. Still need the attach angles on the F-621 decks.

|

|

Roughed in

|

|

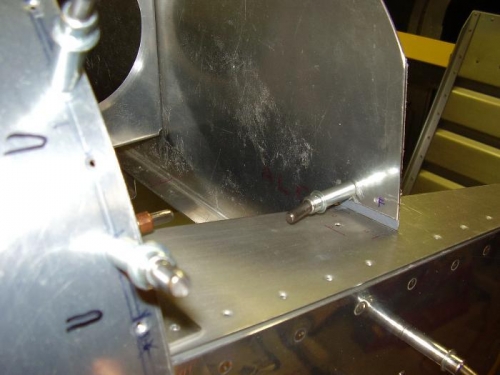

Backside gap

|

|

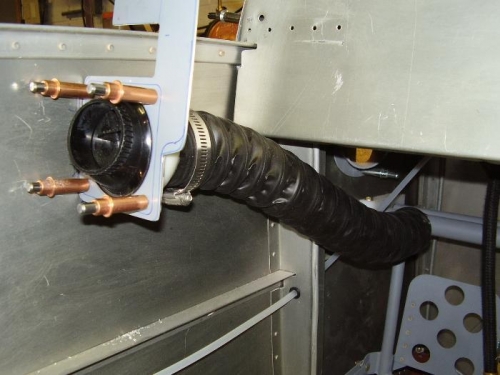

Vent duct

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|