|

|

|

|

Larry Winger's 601XL Project

|

Date: 12-15-2007

|

Number of Hours: 3.50

|

Manual Reference:

|

Brief Description: Cut wire and made/mounted conduit brackets

|

|

I am learning that there are many parts of the project that are open to interpretation or adaptation. Wing wiring is one of them. I've also learned that picking a course of action usually takes longer than making/installing/modifying the parts in question. Once again this was true with wiring. I've given serious consideration for adel clamps, zip ties, waxed lacing tape, grommets through the ribs, etc., etc. In the end, I went with the conduit approach on the advice of Mark Townsend, confirmed by Debo Cox (who followed Scott Laughlin's lead). The only difference is that I chose to use thin-walled 6061-T6 tubing instead of PVC (or similar). I planned on using 5/8", but because they were out of stock at ACS, I went up a size to 3/4". The added weight penalty was minimal and it will provide free access to the wing tip should any kind of re-wiring / new wiring be required. I made the end supports out of .032" using 3/4" grommets. The middle supports don't use any grommets, since their ID is 3/4". Earlier in the day, I cut all the lengths necessary for my landing lights and future nav/position/LED strobes. Each set of lights requires 4 (four) #20 wires.

|

|

Full length of conduit

|

|

Outboard end and #20 wires ready to install

|

|

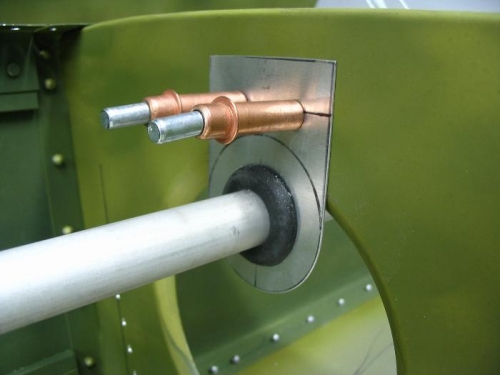

Close up of end support

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|