|

|

|

|

Larry Winger's 601XL Project

|

Date: 3-20-2007

|

Number of Hours: 4.50

|

Manual Reference: 6W4

|

Brief Description: Replaced center spar upright rivets

|

|

My last entry reported that I only had to get longer AN bolts for the side uprights and I'd be ready to close up my center spar in 60 to 90 minutes. On further inspection, I concluded that I had another item to fix, again related to the thickness of my extruded aluminum material used for the center uprights this time. The AN470-AD-5-10 rivets that were specified produced shop heads that were the minimum height and the maximum width. Not wanting to live that close to the edge, I decided to drill out the 5-10s and replace them with 5-12 rivets. In hindsight, I probably should have left well enough alone. In the process of drilling these out, I inadvertently enlarged the holes. When I set the longer rivets, the slop in my alignment caused the new rivets to have gaps under the manufactured head. I really didn't like that, so I decided to drill them out and go to an AN-3-7A bolt. By the time I got out the 2nd set of rivets, my holes were actually larger than the 3/16" needed for the AN3 bolts. I spoke with Caleb at ZAC and he assured me that I could use an AN4 bolt (1/4" grip), but that going beyond that to 5/16" would be questionable. Knowing I had one chance to get it right, I decided to take my front web to my machinist to get perfectly aligned 1/4" holes. He pulled it off in style, and my existing uprights even lined up with with only minor reaming on one hole. AN4-7A bolts worked perfectly and I ended up with a stronger attachment, albeit it heavier, than I had at the beginning of this exercise in frustration. All's well that ends well, especially when no compromises in safety were made.

|

|

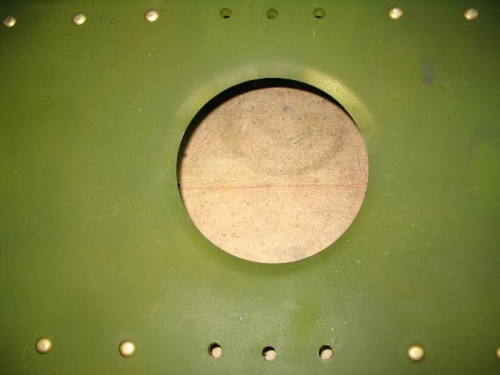

The holes produced by my machinist

|

|

Complete with their new AN4 bolts

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|