|

|

|

|

RV-7 Construction Log

|

Date: 3-3-2013

|

Number of Hours: 3.00

|

Manual Reference:

|

Brief Description: Wings - Aileron Push Tubes

|

|

Today I also went ahead and got started on the aileron push tubes: the W-818's from the aileron bellcrank to the aileron, and the W-716's from the stick to the bellcrank.

The W-818 is made from 1/2" diameter steel tube. Two tubes 23-13/16" are cut from a 48" length of stock, so you have to be relatively careful not to cut one too long. I must have checked my measurements about 5 or 6 times to make sure. After marking, I cut about 1/8" outside the line, then used my belt sander with a 90-deg. fence to grind the tubes to length and square the ends. I ended up with less than 1/4" of stock left over...

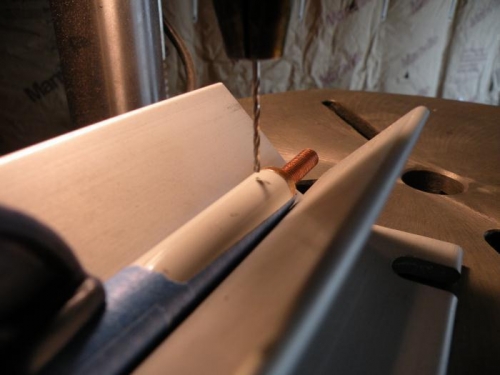

After deburring the tube ends with scotchbrite, I fit and drilled the threaded rod ends. To drill, I taped the threaded rod ends in the tube, then clamped the tube up in a v-jig on my drill press and proceeded through 1/16" and 1/8" drill bits and a #30 reamer(Photo 1). After drilling both holes on both ends of both push tubes, I removed the rod ends, deburred the holes, and primed the inside of the tubes.

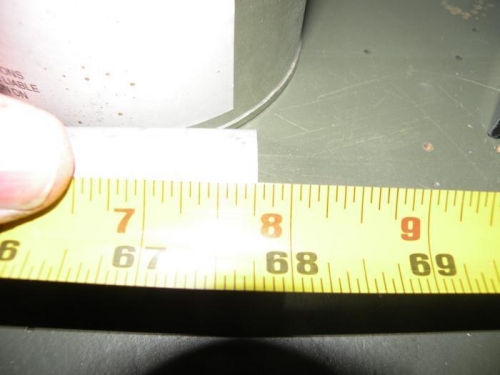

While the primer inside the W-818 tubes was curing, I got started on the W-716 tubes. There are two of these, each 65-25/32" long, cut from 1-1/8 inch x 12-ft Al stock. I got both tubes cut to length using the same technique as for the steel tubes, and deburred the ends. To mark the six rivet holes in the ends, I wrapped a piece of tape around the end, made a lengthwise mark on the tape, cut the tape at the mark, removed the tape, then used my rivet fan to mark six evenly spaced holes 1/4" from the end. I got one end of one tube centerpunched before having to quit for the day.

I did notice that the VA-111 rod ends for this assembly seem a bit loose in the bore of the tube. I wrapped one of the rod ends with one turn of tape and couldn't get it in the tube. After removing a half turn of the tape I could get the rod end in the tube, but it was still slightly loose. I measured the tape at about 0.004" thick, so I'm guessing the rod ends are about 0.005 to 0.006 inches smaller than the bore of the tube.

|

|

W-818 and threaded rod end jigged up for drilling.

|

|

I taped the measuring tape 2-inch mark at the opposite end. Length of the tube is 65-25/32 inches.

|

|

One end of a W-716 push tube marked and center punched for rivet holes.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|