|

|

|

|

RV-7 Construction Log

|

Date: 2-11-2012

|

Number of Hours: 1.50

|

Manual Reference: P 6-7

|

Brief Description: Session 1 - Rudder Assembly - Part 8

|

|

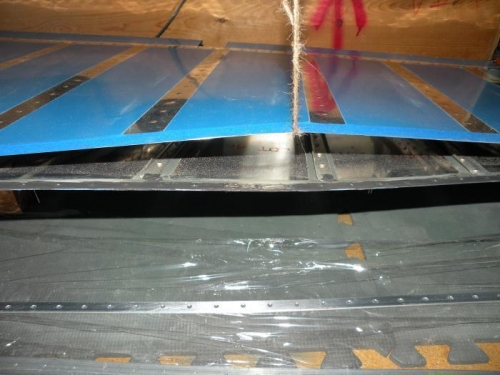

Prosealed the trailing edge of the rudder. I didn't have help, so stealing an idea from another builder, I held the skins open with a piece of twine suspended from a rafter, as shown in Photo 1. The weight of the rudder opens the skins just enough to get in for scuffing, cleaning, and insertion of the AEX wedge. I couldn't find my stainless steel brushes, and scotchbrite didn't get the surfaces rough enough to suit me, so I used 100-grit aluminum oxide sandpaper to scuff the skins and AEX wedge. I then solvent wiped several times until the rag came up clean.

I applied the proseal with an acid brush trimmed down to 1/4 inch, which made the brush stiff enough to spread the proseal into a fairly thin layer. I applied the first layer to the bottom skin, as shown in Photo 2. Next, I inserted the AEX wedge and applied a layer of proseal to the top of that, then 100% clecoed the two angles through the whole assembly. Hopefully this will result in a very straight trailing edge with no pillowing between rivet holes. I moved the assembly into the (warm) spare bedroom for a couple of days to allow the proseal to cure.

The batch of proseal was 17.5 grams, and weighed 7 grams after applicaton, so it took just over 10 grams to do the job.

|

|

Working solo required stealing an idea from another builder.

|

|

First layer of proseal applied to bottom skin trailing edge.

|

|

Trailing edge gluing complete and 100% cleoed between two angles.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|