Date

|

Hours

|

Work Log Summary

|

Details

|

01-23-2022

|

6.00

|

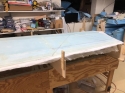

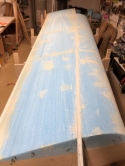

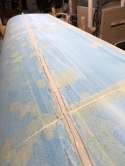

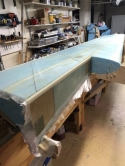

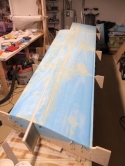

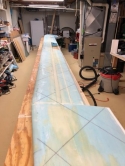

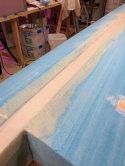

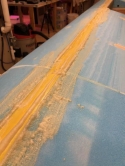

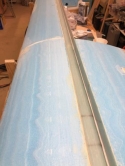

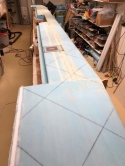

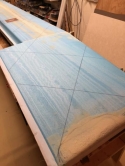

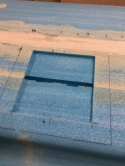

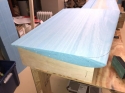

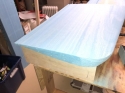

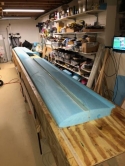

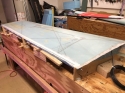

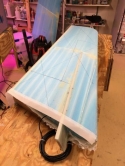

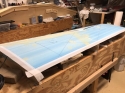

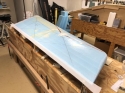

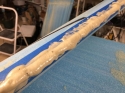

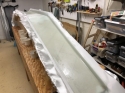

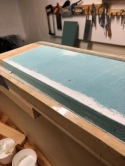

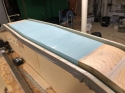

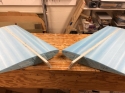

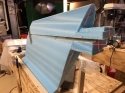

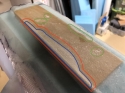

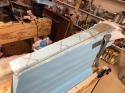

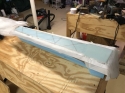

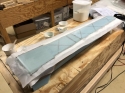

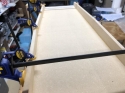

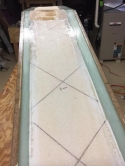

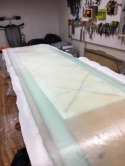

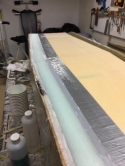

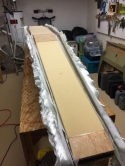

Skin Upper Surface or Right Wing

|

|

|

|

01-23-2022

|

2.00

|

Final Prep Work to Skin Upper Wing

|

Details

|

|

|

01-23-2022

|

1.00

|

Clean up After Skinning Upper Right Wing and finis

|

Details

|

|

|

01-22-2022

|

1.00

|

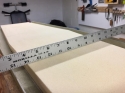

Finish Final Sanding or Right Wing Upper Surface -

|

Details

|

|

|

01-22-2022

|

1.25

|

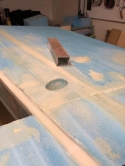

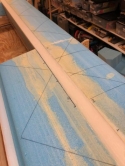

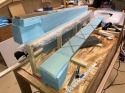

Draw Fiberglass Alignment Lines on Upper Right Win

|

Details

|

|

|

01-22-2022

|

3.00

|

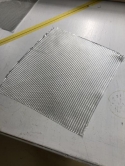

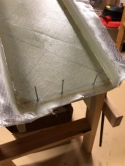

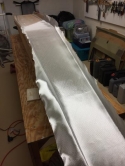

Cut Fiberglass and Peel Ply for Right Wing Upper S

|

Details

|

|

|

01-22-2022

|

0.50

|

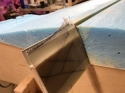

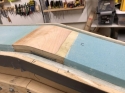

Add Trailing Edge Alignment Supports to Jigs

|

Details

|

|

|

01-21-2022

|

0.50

|

Trim and Prepare Right Wing Upper Wing Bolt Attach

|

Details

|

|

|

01-21-2022

|

1.00

|

Sand Excess Expanding Foam and Add More to Upper R

|

Details

|

|

|

01-21-2022

|

0.50

|

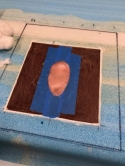

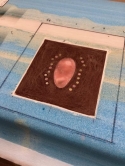

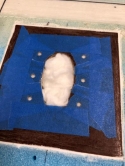

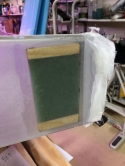

Flox Upper Right Wing Attach Bolt Access Port Inse

|

Details

|

|

|

01-20-2022

|

0.25

|

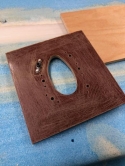

Trim off Excess Fiberglass from Right Wing Upper A

|

Details

|

|

|

01-20-2022

|

1.25

|

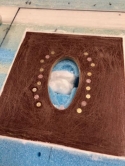

Final Shaping and Fiberglassing of Right Wing Uppe

|

Details

|

|

|

01-20-2022

|

0.30

|

Add Expanding Foam to Continue Repair to Upper Rig

|

Details

|

|

|

01-19-2022

|

0.10

|

Mark off Final Area Where Upper Right Wing Spar N

|

Details

|

|

|

01-19-2022

|

1.25

|

Continue to Work on Right Wing Upper Attach Access

|

Details

|

|

|

01-18-2022

|

1.25

|

Continue Shaping Right Wing Upper Access Port and

|

Details

|

|

|

01-18-2022

|

1.00

|

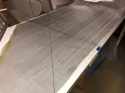

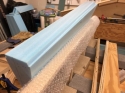

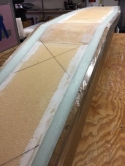

Continue Sanding Right Wing Upper Spar to Final Sh

|

|

|

|

01-17-2022

|

1.25

|

Continue Sanding Upper Right Wing Spar to Shape

|

Details

|

|

|

01-17-2022

|

1.00

|

Begin Cutting Right Wing Upper Wing Bole Attach Po

|

Details

|

|

|

01-16-2022

|

1.25

|

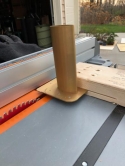

Begin Trimming and Planing off Excess Spar Materia

|

Details

|

|

|

01-15-2022

|

0.50

|

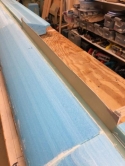

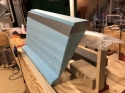

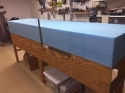

Weight Down Upper Right Wing Spar to Cure

|

Details

|

|

|

01-15-2022

|

1.00

|

Mask Off and Final Sanding and Vacuuming of Right

|

Details

|

|

|

01-15-2022

|

7.00

|

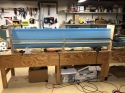

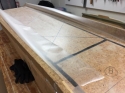

Layup Upper Right Wing Spar

|

|

|

|

01-15-2022

|

0.75

|

Clean All Roving Components with Acetone

|

Details

|

|

|

01-14-2022

|

1.25

|

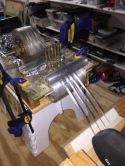

Rebuild Fiberglass Roving Stand to Accurately Posi

|

Details

|

|

|

01-14-2022

|

1.00

|

Put Together and Position S-Glass Roving Wetting W

|

Details

|

|

|

01-13-2022

|

2.00

|

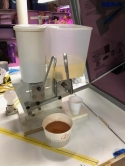

Finish Rebuilding and Re-metering Epoxy Pump for u

|

Details

|

|

|

01-12-2022

|

2.00

|

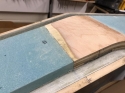

Continue Sanding Expanded Foam on Right Upper Wing

|

Details

|

|

|

01-11-2022

|

2.00

|

Sand Expanded Foam off of Upper Right Wing Surface

|

Details

|

|

|

01-10-2022

|

0.25

|

Finish Trimming Trailing Edge Support Foam

|

Details

|

|

|

01-10-2022

|

1.00

|

Fill Wing Foam Dents with Expanding Foam

|

Details

|

|

|

01-09-2022

|

0.25

|

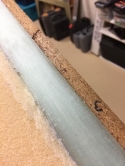

Trim Excess Fiberglass from Spar Stub

|

Details

|

|

|

01-09-2022

|

0.50

|

Trim Excess Fiberglass from Inboard Wing Spar Sect

|

Details

|

|

|

01-09-2022

|

0.50

|

Repair "Snapped" Trailing Edge Corner

|

Details

|

|

|

01-09-2022

|

1.25

|

Fill Shear Web "Gap" with Micro

|

Details

|

|

|

01-09-2022

|

0.50

|

Begin Trimming Excess Support Foam from Wing Trail

|

Details

|

|

|

01-08-2022

|

2.50

|

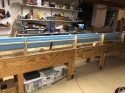

Remove Upper Wing Support Jigs and Replace with Lo

|

Details

|

|

|

01-08-2022

|

0.25

|

Position Wing in Jigs, Upper Surface Up

|

Details

|

|

|

01-03-2022

|

2.00

|

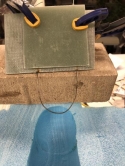

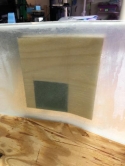

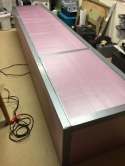

Build and Test Post-Curing Oven

|

Details

|

|

|

01-02-2022

|

1.00

|

Disassemble and Begin Cleaning Epoxy Pump Parts wi

|

Details

|

|

|

01-02-2022

|

0.75

|

Add Another Layer of Micro to Even Out Trailing Ed

|

Details

|

|

|

01-01-2022

|

1.00

|

Trim Off Excess Cured Fiberglass from Sides and Tr

|

Details

|

|

|

01-01-2022

|

0.50

|

Remove Bottom Right Wing Layup Peel Ply

|

Details

|

|

|

01-01-2022

|

1.00

|

Re-align/Re-level Right Wing Trailing Edge

|

Details

|

|

|

12-26-2021

|

5.50

|

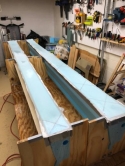

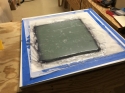

Skin Bottom of the Right Wing

|

Details

|

|

|

12-26-2021

|

1.00

|

Pincushion Bottom Right Wing Foam and Final Vacuum

|

Details

|

|

|

12-26-2021

|

0.50

|

Flox Reinforcement Gap Around Right Wing Bottom Wi

|

Details

|

|

|

12-26-2021

|

0.75

|

Final Vacuum of Lower Right Wing and Check Final A

|

Details

|

|

|

12-24-2021

|

2.50

|

Cut Fiberglass and Peel Ply for Bottom Right Wing

|

Details

|

|

|

12-21-2021

|

0.50

|

Finish Filling Right Wing Lower Surface Dings with

|

Details

|

|

|

12-21-2021

|

1.25

|

Draw Fiberglass Skin Alignment Lines on Lower Righ

|

Details

|

|

|

12-20-2021

|

0.50

|

Add Micro to Finalize Opening Area of Bottom Right

|

Details

|

|

|

12-19-2021

|

0.30

|

Route out Foam Aroung Lower Right Wing Attach Port

|

Details

|

|

|

12-19-2021

|

0.30

|

Finish Final Shaping of Right Wing Lower Attach Bo

|

Details

|

|

|

12-19-2021

|

0.50

|

Cut Out Recessed Area Around Bottom Rt Wing Atch.

|

Details

|

|

|

12-18-2021

|

1.50

|

Finish Sanding Expanding Foam from Lower Side Righ

|

Details

|

|

|

12-16-2021

|

0.75

|

Finish Aligning Right Wing Trailing Edge Supports

|

Details

|

|

|

12-16-2021

|

2.00

|

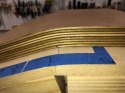

Build Upper Right Wing Spar Dam

|

Details

|

|

|

12-11-2021

|

1.75

|

Add Alignment Strips to Trailing Edges of Jigs

|

Details

|

|

|

12-10-2021

|

0.75

|

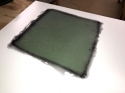

Remove Peel Ply, Trim, and Sand Spar Fiberglass Re

|

Details

|

|

|

12-08-2021

|

1.50

|

Cut and Apply Fiberglass to Spar Section for Repai

|

Details

|

|

|

12-01-2021

|

0.75

|

Flox Insert for Lower Right Wing Attach Bolt Acces

|

Details

|

|

|

12-01-2021

|

0.50

|

Clean up fiberglass on lower right wing attach bol

|

Details

|

|

|

12-01-2021

|

0.50

|

Begin Alignment of Right Wing Trailing Edge

|

Details

|

|

|

11-30-2021

|

1.00

|

Fiberglass Insert for Lower Wing Attach Bolt Acces

|

Details

|

|

|

11-30-2021

|

1.00

|

Clean Up Fiberglass at Wing Attach Port and Shape

|

Details

|

|

|

11-29-2021

|

0.50

|

Sand off delaminated areas from wing shear web ext

|

Details

|

|

|

11-29-2021

|

0.75

|

Reattach wing jigs that had come loose to the work

|

Details

|

|

|

11-29-2021

|

1.75

|

Finish layup of lower right wing attach bolt acces

|

Details

|

|

|

11-28-2021

|

1.25

|

Clean micro off of WA-4B and re-Alodine

|

Details

|

|

|

11-28-2021

|

1.00

|

Begin sanding right wing lower spar to final dimen

|

Details

|

|

|

11-27-2021

|

1.00

|

Use wood planer to begin removing excess spar mate

|

Details

|

|

|

11-27-2021

|

0.50

|

Layout Right Wing Lower Wing Attach Port

|

Details

|

|

|

11-27-2021

|

0.75

|

Layout and cut lower outboard wing attach bolt por

|

Details

|

|

|

11-27-2021

|

0.25

|

Hotwire Right Wing Lower Attach Bolt Access Port

|

Details

|

|

|

11-27-2021

|

0.50

|

Create jig to hotwire cut wing outboard attach bol

|

Details

|

|

|

11-27-2021

|

1.00

|

Build Hotwire Jig to Cut Wing Bolt Attach Ports

|

|

|

|

11-26-2021

|

0.20

|

Remove lower right wing spar dam

|

|

|

|

11-10-2021

|

2.00

|

Finish aligning wing jigs

|

Details

|

|

|

11-09-2021

|

1.25

|

Continue realigning wing jigs for bottom spar and

|

Details

|

|

|

11-02-2021

|

3.50

|

Micro Fore and Aft Right Wing Sections Together

|

Details

|

|

|

10-09-2021

|

0.75

|

Begin rounding over edges of aft secition of wing

|

Details

|

|

|

06-05-2021

|

1.75

|

Begin Bolting Wing Jig Sections Together

|

|

|

|

04-24-2021

|

1.00

|

Sand to Fine Tune Scarf Cuts

|

Details

|

|

|

04-24-2021

|

2.50

|

Cut Scarf Joints on DWA-1, 2, 6, 7, and both 3's.

|

Details

|

|

|

04-24-2021

|

1.00

|

Build Jig to Cut Scarf Joints on Wing Wood Inserts

|

Details

|

|

|

04-22-2021

|

1.00

|

Begin Trimming Out DWA-2 and DWA-7

|

Details

|

|

|

04-21-2021

|

0.75

|

Epoxy Side Plywood Pieces on to DWA-7

|

Details

|

|

|

03-05-2021

|

0.50

|

Work on Trimming Out Wing Templates

|

Details

|

|

|

03-02-2021

|

0.75

|

Examine Canard for Areas Needing Repair

|

Details

|

|

|

02-28-2021

|

1.50

|

Cut out aileron templates

|

|

|

|

02-27-2021

|

2.00

|

Continue fiberglass layup imperfection repairs

|

Details

|

|

|

02-26-2021

|

1.00

|

Finish carving out exposed foam areas in canard.

|

Details

|

|

|

02-26-2021

|

0.75

|

Continue sanding leading edge fiberglass transitio

|

Details

|

|

|

02-25-2021

|

1.75

|

Continue carving out foam from exposed canard area

|

Details

|

|

|

02-23-2021

|

1.25

|

Begin carving out foam from exposed areas of canar

|

Details

|

|

|

02-22-2021

|

2.50

|

Trim Canard Trailing Edge and Start Sanding Leadin

|

Details

|

|

|

02-21-2021

|

0.75

|

Taking care of some minor repairs to the canard la

|

Details

|

|

|

02-20-2021

|

8.00

|

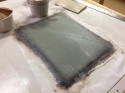

Skin Bottom of Canard

|

Details

|

|

|

02-19-2021

|

0.50

|

Repair Canard Leading Edge with Expanding Foam

|

Details

|

|

|

02-19-2021

|

1.50

|

Cut Fiberglass for Canard Upper Skin Layup

|

Details

|

|

|

02-18-2021

|

2.00

|

Layout Lines for Canard Fiberglass Reinforcement P

|

Details

|

|

|

02-13-2021

|

0.75

|

Flox Canard to Tip Transition Areas

|

Details

|

|

|

02-13-2021

|

0.75

|

Fill Canard Core Joints

|

Details

|

|

|

02-13-2021

|

1.50

|

Feather Canard Trailing Edge Foam and High-Density

|

Details

|

|

|

02-12-2021

|

0.50

|

Add More Expanding Foam Repairs

|

|

|

|

02-08-2021

|

0.50

|

More sanding...

|

Details

|

|

|

02-07-2021

|

2.50

|

Sand off Excess Expanding Foam and Sand High-Densi

|

Details

|

|

|

02-06-2021

|

2.25

|

Plane and Sand Cured Spar Close to Final Shape

|

Details

|

|

|

02-06-2021

|

0.75

|

Add Expanding Foam to Spar/Foam Canard Transition

|

Details

|

|

|

02-05-2021

|

1.00

|

Clean Up Shop after Spar Layup

|

|

|

|

02-04-2021

|

10.50

|

Lay up Upper Canard Spar

|

|

|

|

02-04-2021

|

2.00

|

Final Prep for Upper Canard Spar Layup

|

Details

|

|

|

02-04-2021

|

1.50

|

Clean Up After Canard Spar Layup

|

|

|

|

02-03-2021

|

2.00

|

Build Bridge Over Canard Tip to Hold Roving Wheel

|

Details

|

|

|

02-02-2021

|

0.75

|

Sand to Roughen Up the Sides and Bottom of Upper C

|

Details

|

|

|

02-01-2021

|

0.25

|

Rough-Trim High-Density Foam Inserts

|

Details

|

|

|

01-31-2021

|

0.50

|

Add Additional Micro to High Density Foam Gaps

|

Details

|

|

|

01-30-2021

|

0.50

|

Fill Gap in Fore and Aft Canard Sections with Micr

|

Details

|

|

|

01-30-2021

|

0.50

|

Add Expanding Foam to Repair Leading Edge and Cana

|

Details

|

|

|

01-29-2021

|

0.50

|

Anchor High-Density Foam Blocks into Canard w/Micr

|

Details

|

|

|

01-28-2021

|

1.00

|

Reassemble Epoxy Pump

|

Details

|

|

|

01-27-2021

|

1.00

|

Disassemble and Clean Epoxy Pump Resin Side of Dis

|

Details

|

|

|

01-26-2021

|

2.00

|

Continue to Shape and Dry-Fit High-Density Foam In

|

Details

|

|

|

01-25-2021

|

1.25

|

Continue Carving Holes For High Density Foam Inser

|

Details

|

|

|

01-24-2021

|

1.75

|

Continue Carving Holes For High Density Foam Inser

|

Details

|

|

|

01-22-2021

|

0.75

|

Continue Carving Holes for High Density Foam Inser

|

Details

|

|

|

01-21-2021

|

2.50

|

Fill "Dents" in Foam, Layout Hard Foam Inserts, an

|

Details

|

|

|

01-20-2021

|

2.25

|

Finish Setting Up and Leveling Jigs For Upper Cana

|

Details

|

|

|

01-19-2021

|

2.25

|

Begin Setting Up Jigs for UpperCanard Layup

|

Details

|

|

|

01-17-2021

|

3.50

|

Finish Shaping Trailing Edges of Canard

|

Details

|

|

|

01-16-2021

|

2.25

|

Begin Cleaning up Canard Trailing Edges

|

Details

|

|

|

01-13-2021

|

1.25

|

Remove Jigs from Tabletop and Clean Up

|

Details

|

|

|

01-13-2021

|

0.50

|

Remove Dam and Trim off Excess Fiberglass from Cen

|

Details

|

|

|

01-13-2021

|

2.00

|

Continue Cleaning up Excess Fiberglass from Layup

|

Details

|

|

|

01-11-2021

|

1.00

|

Remove Peel Ply from Canard and begin Trimming Exc

|

Details

|

|

|

01-11-2021

|

1.00

|

Remove Peel Ply From Canard And Begin Trimming Exc

|

Details

|

|

|

01-09-2021

|

7.00

|

Skin Bottom of Canard

|

Details

|

|

|

01-09-2021

|

7.00

|

Skin Bottom Of Canard

|

Details

|

|

|

01-09-2021

|

2.00

|

Prep Canard for Bottom Skin Layup

|

Details

|

|

|

01-09-2021

|

2.00

|

Prep Canard For Bottom Skin Layup

|

Details

|

|

|

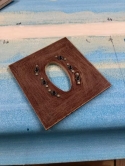

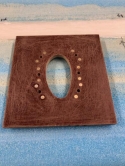

01-04-2021

|

1.25

|

Fill Pitot Tube Support Plate Main Opening with Wa

|

Details

|

|

|

01-04-2021

|

0.50

|

Draw Fiberglass Alignment Lines on Canard

|

Details

|

|

|

01-03-2021

|

0.75

|

Fill Screw Holes in Pitot Tube Support Plate with

|

Details

|

|

|

01-02-2021

|

1.75

|

Cut BID Fiberglass and Cover all Fiberglass to Pr

|

Details

|

|

|

01-01-2021

|

2.00

|

Cut UNI Fiberglass for Bottom of Canard

|

Details

|

|

|

12-31-2020

|

0.25

|

Add Peel Ply to Trailing Edges of Canard

|

Details

|

|

|

12-30-2020

|

2.50

|

Continue to Align Canard in Jigs

|

Details

|

|

|

12-29-2020

|

3.00

|

Continue to Align Canard in Jigs

|

Details

|

|

|

12-28-2020

|

2.25

|

Start Final Alignment of Canard in Jigs

|

Details

|

|

|

12-27-2020

|

1.25

|

Anchor Canard Cores to Jig

|

Details

|

|

|

12-22-2020

|

1.00

|

Sand Pitot Plate and Rivet in Nut Plates

|

Details

|

|

|

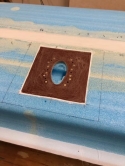

12-22-2020

|

0.50

|

Micro Pitot Tube Support Plate into Canard

|

Details

|

|

|

12-21-2020

|

1.75

|

Route Out Area for Pitot Tube Support Plate

|

Details

|

|

|

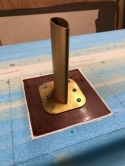

12-18-2020

|

2.00

|

Construct Pitot Tube Support Plate

|

|

|

|

12-16-2020

|

1.25

|

Use Expanding Foam to Perfect Canard Shape

|

Details

|

|

|

12-14-2020

|

0.75

|

Use Expanding Foam to Perfect Canard Shape

|

Details

|

|

|

12-10-2020

|

1.25

|

Use Expanding Foam to Perfect Canard Shape

|

Details

|

|

|

11-24-2020

|

0.25

|

Layout Position for Pitot Tube Support Plate

|

Details

|

|

|

11-24-2020

|

0.50

|

Begin Shaping Right Side Canard Tip

|

Details

|

|

|

11-23-2020

|

1.50

|

Finish Shaping Right Side Canard Tip

|

Details

|

|

|

11-22-2020

|

1.25

|

Continue Shaping Right Side Canard Tip

|

Details

|

|

|

11-21-2020

|

0.75

|

Sand Filled Canard Wire Channel Smooth

|

Details

|

|

|

11-21-2020

|

1.00

|

Begin Shaping Right Side Canard Tip

|

Details

|

|

|

11-21-2020

|

0.75

|

Begin Shaping Left Side Canard Tip

|

Details

|

|

|

11-20-2020

|

0.75

|

Fill Canard Wire Channel with Expanding Foam

|

Details

|

|

|

11-19-2020

|

1.75

|

Shape Pitot Tube Base

|

Details

|

|

|

11-19-2020

|

0.75

|

Final Shaping of Pitot Tube Support Mast

|

Details

|

|

|

11-18-2020

|

0.50

|

Drill Holes in Pitot Support Mast Base

|

Details

|

|

|

11-17-2020

|

1.50

|

Micro Canard Tips to Canard

|

Details

|

|

|

11-10-2020

|

2.25

|

Align Canard Tips in Jigs

|

Details

|

|

|

11-04-2020

|

0.75

|

Final Sand Epanding Foam

|

Details

|

|

|

11-02-2020

|

1.25

|

Sand Canard Spar Expanding Foam

|

Details

|

|

|

11-01-2020

|

1.00

|

Add Expanding Foam Along Canard Spar Edges

|

Details

|

|

|

10-25-2020

|

2.25

|

Sand Canard Spar Flush

|

Details

|

|

|

10-23-2020

|

13.50

|

Lay Up Bottom Canard Spar

|

Details

|

|

|

10-18-2020

|

1.25

|

Build and Install Lower Spar Bridge Dam

|

Details

|

|

|

10-10-2020

|

1.50

|

Fianl Sanding of Expanded Foam Repairs

|

Details

|

|

|

10-01-2020

|

1.25

|

Use Expanding Foam to Repair Canard Foam Damage Ar

|

Details

|

|

|

09-17-2020

|

1.00

|

Tech Counselor Inspection - Pall Mcallister

|

Details

|

|

|

09-13-2020

|

3.00

|

Finish Canard Jig Alignment

|

Details

|

|

|

09-05-2020

|

2.50

|

Remove Vertical Canard Jigs and Begin Realignment

|

Details

|

|

|

09-03-2020

|

1.50

|

Micro Fore and Aft Canard Sections Together

|

|

|

|

09-01-2020

|

1.75

|

Final Canard Core Alignment

|

|

|

|

08-26-2020

|

1.75

|

Work on Canard Core Alignment

|

Details

|

|

|

08-25-2020

|

1.50

|

Finish Canard Jig Construction

|

Details

|

|

|

08-23-2020

|

0.75

|

Trim fiberglass of second edge of canard forward s

|

Details

|

|

|

08-20-2020

|

6.50

|

Layup Forward Section Shear Web

|

Details

|

|

|

08-18-2020

|

2.00

|

Cut Fiberglass for Canard Sheer Web

|

Details

|

|

|

08-16-2020

|

0.75

|

Finish Shaping Canard Core Edges

|

|

|

|

07-07-2020

|

1.00

|

Roundover Canard Leading Edge Core Edges

|

Details

|

|

|

06-13-2020

|

2.25

|

Micro Canard Leading Edge Cores Together

|

|

|

|

06-12-2020

|

2.75

|

Micro Canard Trailing Cores Together

|

Details

|

|

|

06-11-2020

|

4.00

|

Micro leading edge canard cores together

|

Details

|

|

|

06-10-2020

|

3.50

|

Work on Aligning Canard Jigs and Cores

|

|

|

|

06-10-2020

|

6.00

|

Adjust foreward canard core lengths

|

Details

|

|

|

05-28-2020

|

6.00

|

Set up jigs for forward canard core assembly

|

Details

|

|

|

05-26-2020

|

1.00

|

Trim out shear webs on canard trailing cores

|

Details

|

|

|

05-23-2020

|

2.00

|

Lay up aft canard sections shear webs

|

Details

|

|

|

05-22-2020

|

1.50

|

Cut UNI fiberglass for canard trailing edge shear

|

Details

|

|

|

05-21-2020

|

2.00

|

Clean up trailing canard cores and place in jigs

|

Details

|

|

|

05-19-2020

|

1.00

|

Micro together second pair of trailing edge canard

|

Details

|

|

|

05-17-2020

|

1.50

|

Micro'd together two of the training edge foam cor

|

Details

|

|

|

05-16-2020

|

2.00

|

Test assemble one set of training edge cores

|

Details

|

|

|

05-14-2020

|

1.50

|

Test fit trailing edge cores into jigs.

|

Details

|

|

|

05-10-2020

|

4.00

|

Set up canard jigs for training edge core ass

|

Details

|

|

|

05-04-2020

|

3.50

|

Hotwire split in canard cores for shear web

|

Details

|

|

|

04-28-2020

|

1.50

|

Use expanding foam to repair hotwire error on one

|

Details

|

|

|

04-28-2020

|

1.00

|

Final sand repair to canard and rudder cores

|

|

|

|

04-15-2020

|

4.00

|

Use expanding foam to repair one canard tip and ru

|

Details

|

|

|

04-14-2020

|

6.00

|

Construct canard jigs

|

Details

|

|

|

04-13-2020

|

2.00

|

Micro new leading edge section to damaged canard t

|

Details

|

|

|

04-03-2020

|

1.50

|

Trim out roots of both winglets. WINGLETS DONE!

|

Details

|

|

|

04-02-2020

|

2.00

|

Close out root of winglet #2

|

Details

|

|

|

04-01-2020

|

2.00

|

Close out root of winglet #1

|

Details

|

|

|

03-26-2020

|

2.00

|

Cut blanks and mark layout lines for canard jigs

|

Details

|

|

|

03-25-2020

|

0.50

|

Trim out winglet #2

|

Details

|

|

|

03-24-2020

|

1.00

|

Prepare fiberglass for close out of winglet bases

|

Details

|

|

|

03-23-2020

|

3.00

|

Skin side 2 of winglet #2 with two plies of UNI an

|

Details

|

|

|

03-21-2020

|

3.00

|

Skin side 1 of winglet #2 with 2 layers UNI and pe

|

Details

|

|

|

03-21-2020

|

0.75

|

Make small repairs to trailing edge of winglet #1

|

|

|

|

03-15-2020

|

1.50

|

Set up winglet jigs and winglet #2 for skinning

|

Details

|

|

|

03-14-2020

|

1.50

|

Prep second winglet for first fiberglass skin layu

|

Details

|

|

|

03-14-2020

|

0.50

|

Continue work on antenna in second winglet

|

Details

|

|

|

03-13-2020

|

1.50

|

Install antenna in second winglet

|

Details

|

|

|

03-12-2020

|

0.50

|

Carve channel for coax antenna lead in winglet #2

|

Details

|

|

|

03-07-2020

|

1.00

|

FINISHED MAIN SPAR!!

|

Details

|

|

|

03-05-2020

|

2.25

|

Lay up 4 layers of UNI on top of main spar

|

|

|

|

03-02-2020

|

1.75

|

Sand spar #2 in main spar to final dimension

|

Details

|

|

|

02-29-2020

|

9.00

|

Layup spar #2 in main spar and peel ply

|

Details

|

|

|

02-27-2020

|

1.50

|

Trim training edge of winglet #1 and remove wingle

|

Details

|

|

|

02-24-2020

|

2.00

|

Sand spar #1 in main spar to final dimension

|

Details

|

|

|

02-23-2020

|

3.50

|

Layup outboard side of winglet #1 with 2 plys of U

|

Details

|

|

|

02-21-2020

|

11.00

|

Lay up Spar 1 in main spar and Peel Ply - LONG day

|

Details

|

|

|

02-15-2020

|

3.00

|

Layup inboard side of winglet #1 with two plys of

|

Details

|

|

|

02-14-2020

|

0.50

|

Prepare winglet #1 for layup #1

|

|

|

|

02-10-2020

|

2.75

|

Set up winglet #1 on jigs

|

|

|

|

02-04-2020

|

0.75

|

Sand winglet #1 leading edge and fill expanding fo

|

Details

|

|

|

02-03-2020

|

0.75

|

Mask off leading edge of winglet and fill coax cha

|

Details

|

|

|

02-02-2020

|

1.75

|

Embed coax in leading edge of winglet #1 and micro

|

Details

|

|

|

02-01-2020

|

2.00

|

Install copper foil antenna in winglet #1, solder

|

Details

|

|

|

01-31-2020

|

0.75

|

Cut channel for coax in winglet core #1 and prepar

|

Details

|

|

|

01-25-2020

|

1.25

|

Layout location for winglet antenna

|

Details

|

|

|

01-25-2020

|

1.25

|

Finalize shaping of foam and wood inserts in main

|

Details

|

|

|

01-21-2020

|

2.50

|

Construct drilling jig and drill hole in winglet c

|

Details

|

|

|

01-20-2020

|

2.50

|

Shape top foam piece of main spar

|

Details

|

|

|

01-18-2020

|

0.50

|

Continue using expanding foam to repair winglet co

|

Details

|

|

|

01-16-2020

|

0.50

|

Continue using expanding foam to repair winglet co

|

Details

|

|

|

01-04-2020

|

1.00

|

Inspect hard point adhesion and cut foam insert te

|

Details

|

|

|

01-04-2020

|

1.25

|

Epoxy all main spar foam inserts into place

|

Details

|

|

|

01-04-2020

|

1.25

|

Cut main spar foam inserts

|

Details

|

|

|

01-03-2020

|

0.75

|

Use expanding foam to repair winglet dings.

|

Details

|

|

|

01-02-2020

|

1.25

|

Epoxy hard point laminates into spar

|

Details

|

|

|

01-01-2020

|

1.50

|

Trim out first spar layup

|

Details

|

|

|

12-31-2019

|

0.50

|

Shape top of winglet #1

|

Details

|

|

|

12-24-2019

|

5.50

|

Finish canard templates and cut all canard cores

|

Details

|

|

|

12-23-2019

|

6.25

|

Redo 6-layer base fiberglass layup

|

Details

|

|

|

11-10-2019

|

0.75

|

Epoxy hardpoints into main spar DWA's

|

Details

|

|

|

11-09-2019

|

4.25

|

Layup 6-layer fiberglass base layup

|

Details

|

|

|

11-08-2019

|

0.75

|

Trim out hard point inserts for main spar

|

Details

|

|

|

11-08-2019

|

0.50

|

Line main spar jig with contact release paper

|

Details

|

|

|

11-08-2019

|

1.25

|

Cut fiberglass for main spar lauyups

|

Details

|

|

|

11-05-2019

|

3.25

|

Lay up 1/4" thick fiberglass plate for hard points

|

Details

|

|

|

11-03-2019

|

1.75

|

Route out for hardpoint inserts in DWA-4 and DWA-8

|

Details

|

|

|

10-27-2019

|

1.75

|

Cut and laminate two DWA-5's

|

Details

|

|

|

10-25-2019

|

2.25

|

Trim to final size DWA-4 and DWA-8

|

Details

|

|

|

09-25-2019

|

0.25

|

Final laminate for DWA-4 and DWA-8. Looking good!

|

Details

|

|

|

09-23-2019

|

2.50

|

Layup DWA-8 Laminate

|

Details

|

|

|

09-21-2019

|

2.25

|

Layup DWA-4 Laminate

|

Details

|

|

|

09-20-2019

|

8.00

|

Construct solid block form for DWA-4 and DWA-8

|

Details

|

|

|

09-11-2019

|

1.00

|

Determined that spar was unacceptable and destroy.

|

Details

|

|

|

07-04-2019

|

9.00

|

Lay up second spar in centersection spar.

|

Details

|

|

|

06-23-2019

|

11.00

|

Lay up first spar in centersection spar.

|

Details

|

|

|

06-20-2019

|

1.00

|

Cut a template from the drawings on the plans and

|

Details

|

|

|

06-20-2019

|

2.50

|

Build jig and drill hole for antenna coax cable in

|

Details

|

|

|

06-14-2019

|

0.75

|

Repair edges of center foam section for main spar

|

Details

|

|

|

06-11-2019

|

0.50

|

Sand micro joint smooth on second winglet.

|

Details

|

|

|

06-09-2019

|

2.00

|

Use epoxy and micro to attach upper and lower wing

|

Details

|

|

|

06-06-2019

|

0.50

|

Sand micro joint smooth on first winglet.

|

Details

|

|

|

06-04-2019

|

2.00

|

Use epoxy and micro to attach upper and lower wing

|

Details

|

|

|

06-02-2019

|

0.10

|

Inspecting underside of centersection spar. I wil

|

Details

|

|

|

06-01-2019

|

0.50

|

Sand down high point edges of curved wooden sectio

|

Details

|

|

|

05-30-2019

|

2.50

|

Finish sanding middle foam section of centersectio

|

Details

|

|

|

05-27-2019

|

2.00

|

Began to sand additional high density foam piece i

|

Details

|

|

|

05-26-2019

|

1.75

|

Unmold spar from jig and trim fiberglass edges.

|

Details

|

|

|

05-25-2019

|

0.75

|

Epoxy second piece of foam to forward face of main

|

Details

|

|

|

05-24-2019

|

3.50

|

Lay in 6 layers of UNI into main spar jig.

|

Details

|

|

|

05-24-2019

|

3.00

|

Install foam and laminated wood pieces into main s

|

Details

|

|

|

05-21-2019

|

1.50

|

Finish cutting last piece of foam and finished tri

|

Details

|

|

|

05-20-2019

|

1.50

|

Final trimming and fitting of foam inserts for ma

|

Details

|

|

|

05-19-2019

|

2.00

|

Rough cut foam inserts for main spar and start to

|

Details

|

|

|

05-18-2019

|

2.50

|

Make final alignment for main spar wood inserts an

|

Details

|

|

|

05-13-2019

|

1.00

|

Finish sanding lower winglet spars.

|

Details

|

|

|

05-02-2019

|

2.00

|

Layup second spars in lower winglets.

|

Details

|

|

|

05-01-2019

|

0.75

|

Prep lower winglet channels for second spar layup.

|

Details

|

|

|

04-30-2019

|

1.50

|

Plane and sand first spars on lower winglets to fi

|

Details

|

|

|

04-29-2019

|

1.50

|

Finished cutting apart lower winglets after curing

|

Details

|

|

|

04-28-2019

|

3.00

|

Layup lower winglet spar #1

|

Details

|

|

|

04-27-2019

|

1.00

|

Final prep for winglet spar layup #1.

|

Details

|

|

|

04-24-2019

|

1.00

|

Finish filling in gaps in spar "trough" with flox

|

Details

|

|

|

04-22-2019

|

0.75

|

Begin filling in gaps between shear web layups wit

|

Details

|

|

|

04-21-2019

|

1.00

|

Flox together Fore and Aft sections of lower wingl

|

Details

|

|

|

04-21-2019

|

0.75

|

Begin final alignment markup on centersection spar

|

Details

|

|

|

04-19-2019

|

2.00

|

Use Wet Flox to Attach Fore Lower Winglet Section

|

Details

|

|

|

04-19-2019

|

1.00

|

Use Flox to Epoxy all 4 Fiberglass Hardpoints into

|

Details

|

|

|

04-19-2019

|

0.25

|

Test Wetout of New Spar Roving. Seemed to Wetout

|

Details

|

|

|

04-19-2019

|

0.25

|

Put Roving and Silica Gel Packets in Gasketed Stor

|

Details

|

|

|

04-18-2019

|

1.20

|

Rout Out Area for Fiberglass Hardpoints in DWA-4 a

|

Details

|

|

|

04-17-2019

|

0.75

|

Trim Away Support Foam to Allow for Laser Alignmen

|

Details

|

|

|

04-16-2019

|

1.75

|

Repair Air Bubble in Winglet #1 Stub

|

Details

|

|

|

04-11-2019

|

1.25

|

Trim all Fore and Aft Lower Winglet Shear Webs.

|

Details

|

|

|

04-09-2019

|

1.75

|

Layup Aft Lower Winglet #2 Shear Web.

|

Details

|

|

|

04-07-2019

|

1.25

|

Prep Aft Section of Lower Winglet #2 for Shear Web

|

Details

|

|

|

04-07-2019

|

1.25

|

Cut Out Hard Points for Main Spar Inserts

|

Details

|

|

|

03-31-2019

|

2.50

|

Layup Aft Shear Web on Lower Winglet #1

|

Details

|

|

|

03-30-2019

|

1.25

|

Layup Forward Shear Web on Lower Winglet #2

|

Details

|

|

|

03-29-2019

|

2.00

|

Prep Forward Section of One Winglet and Layup Shea

|

Details

|

|

|

03-28-2019

|

2.00

|

Layup 21 plies for 1/4" Hardpoints for Main Spar

|

Details

|

|

|

03-23-2019

|

1.50

|

Sand main spar jog side rails to final dimensions

|

Details

|

|

|

03-21-2019

|

3.00

|

Cut fiberglass for first main spar layup, lower wi

|

Details

|

|

|

03-20-2019

|

0.50

|

Apply final rails to main spar jig

|

Details

|

|

|

03-17-2019

|

0.60

|

Add two more rails to main spar jig sides

|

Details

|

|

|

03-16-2019

|

0.30

|

Attach MJS 5 to main spar jig

|

Details

|

|

|

03-15-2019

|

4.00

|

Attach foam extensions to lower winglets

|

Details

|

|

|

03-12-2019

|

2.00

|

Trim foam from lower winglets for shear web layup

|

Details

|

|

|

03-11-2019

|

2.00

|

Cut foam supports for shear web extensions for low

|

Details

|

|

|

03-03-2019

|

0.25

|

Success! Shear web on the test looks great! Now

|

Details

|

|

|

03-03-2019

|

0.25

|

Re-attach lower trimmed sections to winglets

|

Details

|

|

|

03-02-2019

|

2.00

|

Test lower winglet shear web layup using "poor man

|

Details

|

|

|

03-01-2019

|

1.50

|

Build jig to hold lower winglet sections during sh

|

Details

|

|

|

02-28-2019

|

2.50

|

Trim out DWA-8 and DWA-4 to final shape.

|

Details

|

|

|

02-25-2019

|

1.50

|

Layup 8-ply plywood laminate for DWA-4

|

Details

|

|

|

02-25-2019

|

0.30

|

Add final end pieces to DWA-5's

|

Details

|

|

|

02-24-2019

|

2.00

|

Reinforce Jig prior to bending DWA-4

|

Details

|

|

|

02-18-2019

|

1.50

|

Laminate 8 plys for DWA-8

|

Details

|

|

|

02-14-2019

|

1.00

|

Cut new wooden parts to test new method to make DW

|

Details

|

|

|

02-10-2019

|

4.00

|

Cut first DWA-8 to final shape and size

|

Details

|

|

|

02-09-2019

|

0.25

|

Sand/clean up channels in one lower winglet core f

|

Details

|

|

|

02-09-2019

|

2.50

|

Define ends of main spar on jig

|

Details

|

|

|

02-07-2019

|

0.50

|

Laminate base 3-layers of plywood for DWA-5's

|

Details

|

|

|

02-06-2019

|

0.75

|

Epoxy leading edge pieces of .7" cutoffs of lower

|

Details

|

|

|

02-05-2019

|

4.40

|

Epoxy lower winglet leading edge pieces together

|

Details

|

|

|

02-04-2019

|

2.00

|

Bend plywood sheets for DWA-8 and DWA 4

|

Details

|

|

|

02-02-2019

|

1.75

|

Cut .7" from bottom of lower winglet cores

|

Details

|

|

|

01-12-2019

|

1.50

|

Remove lower winglet leading edge for shear web la

|

Details

|

|

|

01-09-2019

|

3.50

|

Re-cut lower winglet cores

|

Details

|

|

|

01-03-2019

|

2.50

|

Test three methods to prevent shear web lifting

|

Details

|

|

|

09-01-2018

|

2.50

|

Cut all winglet jigs

|

Details

|

|

|

07-22-2018

|

1.00

|

Cut two Winglet WWA-1's

|

Details

|

|

|

07-21-2018

|

1.50

|

Beginning lower winglet shear web construction

|

Details

|

|

|

07-20-2018

|

1.50

|

Cut templates to cut winglet shear web

|

Details

|

|

|

07-18-2018

|

0.25

|

Reattach .7" bottom sections to lower winglets.

|

Details

|

|

|

07-16-2018

|

0.75

|

Laminate WWA-1's and DWA-5's

|

Details

|

|

|

07-16-2018

|

2.00

|

Attach leading edge sections to lower winglets.

|

Details

|

|

|

07-16-2018

|

0.25

|

Attach leading edge pieces to .7" winglet cutoff s

|

Details

|

|

|

07-15-2018

|

1.50

|

Test laminate DWA-4 and DWA-8's

|

Details

|

|

|

07-14-2018

|

0.50

|

Cut off lower .7" of lower winglet sections

|

Details

|

|

|

07-10-2018

|

2.25

|

Re-Hotwire New FC-10 Blank

|

Details

|

|

|

07-09-2018

|

1.00

|

Cut blanks for Winglet Jigs

|

Details

|

|

|

07-08-2018

|

1.00

|

Add internal bridges and top to main spar jig

|

Details

|

|

|

07-07-2018

|

0.25

|

Join halves of main spar jig together

|

Details

|

|

|

07-06-2018

|

4.00

|

Successfully cut all 4 winglet cores

|

Details

|

|

|

07-04-2018

|

2.00

|

Successfully hotwire FC-2, FC-3, FC-11 and FC-12 W

|

Details

|

|

|

07-03-2018

|

0.75

|

Add internal supports for main spar jig

|

Details

|

|

|

07-02-2018

|

1.00

|

Continue laying out winglet layout lines

|

Details

|

|

|

07-02-2018

|

1.00

|

Continue gluing up main spar jig

|

Details

|

|

|

07-01-2018

|

0.50

|

Layout template alignments lines for FC-17 lower w

|

Details

|

|

|

07-01-2018

|

2.00

|

Finsih truing up foam billets and layout template

|

Details

|

|

|

07-01-2018

|

0.50

|

Begin gluing up main spar jig

|

Details

|

|

|

06-30-2018

|

4.00

|

Assemble replacement foam billet blanks for wing c

|

Details

|

|

|

06-29-2018

|

3.00

|

Begin putting together new main wing foam billets

|

Details

|

|

|

06-28-2018

|

1.50

|

Test cut winglet with new power supply and wire in

|

Details

|

|

|

06-25-2018

|

1.50

|

Finish prepping foam for winglet cutting test

|

Details

|

|

|

06-22-2018

|

0.50

|

Evaluate hardpoint test

|

Details

|

|

|

06-20-2018

|

1.25

|

Assemble foam blanks for winglets

|

Details

|

|

|

06-19-2018

|

1.00

|

Make test layup of bent hardpoints

|

Details

|

|

|

06-17-2018

|

0.50

|

Adjust bending jig alignment guides to fit

|

Details

|

|

|

06-16-2018

|

1.00

|

Add alignment guides to bending jig.

|

Details

|

|

|

06-15-2018

|

0.25

|

Finish sanding MSJ-1's and test final angle.

|

Details

|

|

|

06-14-2018

|

1.50

|

Cut MSJ-1's, 10's, 11's, and 12's.

|

Details

|

|

|

06-14-2018

|

0.25

|

Begin sanding MSJ-1's to final shape and size.

|

Details

|

|

|

06-10-2018

|

0.75

|

Finish gluing up bending jig

|

Details

|

|

|

06-07-2018

|

0.50

|

Continue guling up bending jig

|

Details

|

|

|

06-04-2018

|

0.50

|

Glue up first part of bending jig

|

Details

|

|

|

05-31-2018

|

0.75

|

Finish cutting all parts for DWA-4 and 8 Bending J

|

Details

|

|

|

05-30-2018

|

1.50

|

Layout DWA 4 and 8 bending jig can cut first piece

|

Details

|

|

|

05-29-2018

|

0.50

|

Continue trimming out wood for Main Spar jig

|

Details

|

|

|

05-28-2018

|

1.25

|

Rough cut wood for Main Spar jig and DWA-4 & 8 Ben

|

Details

|

|

|

04-07-2018

|

1.50

|

Trim foam blank for second lower winglet

|

Details

|

|

|

03-31-2018

|

2.00

|

Trim second set of replacement foam billets for la

|

Details

|

|

|

03-27-2018

|

2.00

|

Trim first set of replacement foam billets for la

|

Details

|

|

|

03-05-2018

|

0.10

|

NEW FOAM!!!

|

Details

|

|

|

02-13-2018

|

2.00

|

Test New Hotwire Saw

|

Details

|

|

|

08-26-2017

|

1.50

|

Remaking a few templates

|

Details

|

|

|

08-05-2017

|

0.50

|

Cut Main Spar in Half

|

Details

|

|

|

05-29-2017

|

1.50

|

Build new hotwire saw.

|

Details

|

|

|

05-28-2017

|

0.25

|

Cut wood for new hotwire saw.

|

Details

|

|

|

05-27-2017

|

0.25

|

Test cut core - Kind of a C+ result.

|

Details

|

|

|

05-26-2017

|

1.00

|

Drill holes in small squares and prep for long cut

|

Details

|

|

|

05-26-2017

|

1.50

|

Cut test templates for hotwire trial

|

Details

|

|

|

05-25-2017

|

3.00

|

Trim out a portion of Black Billet

|

|

|

|

05-24-2017

|

3.00

|

Trim out Blue Billet

|

|

|

|

05-23-2017

|

1.50

|

Set up cutting table for straight cuts

|

|

|

|

05-22-2017

|

2.00

|

Trim out Green Billet

|

Details

|

|

|

05-21-2017

|

2.00

|

Square off and set up for long diagonal cut on Gre

|

Details

|

|

|

05-20-2017

|

3.00

|

Trim out Brown Billet

|

Details

|

|

|

05-19-2017

|

3.00

|

Trim out Red Billet

|

Details

|

|

|

05-18-2017

|

3.00

|

Trim out Orange Billet

|

Details

|

|

|

05-17-2017

|

2.00

|

Square off first new Buoyancy Billets

|

Details

|

|

|

04-16-2017

|

2.00

|

Glue new template sheets to formica sheet.

|

Details

|

|

|

04-14-2017

|

4.50

|

Printing new sheets for templates

|

Details

|

|

|

02-18-2017

|

3.00

|

Finish squaring off first foam block and cutting t

|

Details

|

|

|

02-11-2017

|

4.50

|

Start trimming out first foam block.

|

Details

|

|

|

02-04-2017

|

0.50

|

The spar is finished!

|

Details

|

|

|

02-03-2017

|

0.75

|

Baking the Centersection Spar for 15 hours at a ni

|

Details

|

|

|

02-02-2017

|

2.00

|

Install spar in jig, and finish prepping for post-

|

Details

|

|

|

01-31-2017

|

0.50

|

Modify bulb setup to prevent overheating

|

Details

|

|

|

01-30-2017

|

1.50

|

Test heating of post-cure oven.

|

Details

|

|

|

01-29-2017

|

2.25

|

Build bottom of post-cure oven and position light

|

|

|

|

01-28-2017

|

0.25

|

Caulk inside seams of top of post-cure oven.

|

Details

|

|

|

01-28-2017

|

2.00

|

Build Light bar heat source for post-cure oven.

|

Details

|

|

|

01-27-2017

|

2.00

|

Assemble top of Post-Cure Oven

|

Details

|

|

|

01-23-2017

|

2.00

|

Assembling foam planks for sides and top of post-c

|

Details

|

|

|

01-21-2017

|

0.50

|

Purchase foam for post-cure oven. Construction st

|

Details

|

|

|

01-11-2017

|

0.50

|

Tried a different hair dryer but only on high heat

|

Details

|

|

|

01-10-2017

|

1.25

|

Construct and test post cure plastic oven.

|

Details

|

|

|

01-09-2017

|

1.00

|

Trim out finished centersection spar!

|

Details

|

|

|

01-07-2017

|

0.50

|

Slurry foam and wet out foam and spar caps with ep

|

Details

|

|

|

01-07-2017

|

4.50

|

Layup 4 layers UNI and final peel-ply on Forward F

|

Details

|

|

|

01-07-2017

|

1.50

|

Final sanding of centersection spar, masking & lin

|

Details

|

|

|

01-04-2017

|

1.00

|

Mask off spar caps and feather foam and wood trans

|

Details

|

|

|

01-04-2017

|

1.25

|

Cut UNI and peel ply for final centersection spar

|

Details

|

|

|

01-03-2017

|

2.50

|

Clean the shop!

|

Details

|

|

|

01-01-2017

|

2.00

|

Finish cleanup of spar caps

|

|

|

|

01-01-2017

|

0.25

|

Add alignment lines for final UNI layup on centers

|

Details

|

|

|

12-27-2016

|

1.50

|

Plane down excess roving on spar caps

|

Details

|

|

|

12-25-2016

|

0.75

|

Remove peel-ply from spar cap layup and continue c

|

Details

|

|

|

12-24-2016

|

1.00

|

Begin cleanup after second centersection spar cap

|

Details

|

|

|

12-23-2016

|

9.00

|

Finish second centersection spar cap layup.

|

Details

|

|

|

12-23-2016

|

2.00

|

Epoxy up to temperature, begin centersection spar

|

Details

|

|

|

12-22-2016

|

1.00

|

Pre-measure epoxy for second spar cap layup.

|

Details

|

|

|

12-21-2016

|

1.00

|

Remove duct tape and start cleanup of spar cap.

|

Details

|

|

|

12-17-2016

|

11.00

|

Layup first Centersection spar - and, the aftermat

|

Details

|

|

|

12-17-2016

|

2.00

|

Finish prep work for centersection spar layup

|

Details

|

|

|

12-14-2016

|

2.50

|

Finish construction and testing of roving "de-sizi

|

Details

|

|

|

12-11-2016

|

2.00

|

Sand Centersection Spar "Troughs"

|

Details

|

|

|

12-01-2016

|

0.75

|

Test MGS Epoxy

|

Details

|

|

|

12-01-2016

|

1.25

|

Continue working on roving de-sizing fixture

|

Details

|

|

|

11-29-2016

|

2.00

|

Begin construction of roving "anti-sizing" fixture

|

Details

|

|

|

11-20-2016

|

0.50

|

Begin checking airfoil templates for accuracy. Sl

|

Details

|

|

|

11-19-2016

|

1.50

|

Begin adding roving only to find out that my rovin

|

Details

|

|

|

11-18-2016

|

1.00

|

Final prep of roving setup and prep of centersecti

|

Details

|

|

|

11-17-2016

|

1.00

|

Setup roving area with main spar. Tomorrow night

|

Details

|

|

|

11-17-2016

|

2.00

|

Assemble roving support/dispensing stand.

|

Details

|

|

|

11-16-2016

|

1.00

|

Finish constructing roving support/dispensing stru

|

Details

|

|

|

11-16-2016

|

1.00

|

Construct roving roller

|

Details

|

|

|

11-15-2016

|

2.00

|

Prepare final parts for roving support structure

|

Details

|

|

|

11-14-2016

|

2.00

|

Begin construction of the roving support stand.

|

Details

|

|

|

11-13-2016

|

1.50

|

Final smoothing of foam to plywood transitions of

|

Details

|

|

|

11-13-2016

|

0.75

|

Back to the original roving plan. 8 strands look l

|

Details

|

|

|

11-13-2016

|

0.50

|

A little more cleanup needed but almost ready for

|

Details

|

|

|

11-12-2016

|

0.50

|

Creating an add-on to the wetting wheel to allow f

|

Details

|

|

|

11-11-2016

|

2.50

|

....sand, sand, sand, sand, sand...DONE!!

|

Details

|

|

|

11-10-2016

|

2.00

|

Sand, sand, sand, sand, sand.....

|

Details

|

|

|

11-10-2016

|

0.25

|

Attached metal guards to protect fibreglass edges

|

Details

|

|

|

11-09-2016

|

1.25

|

Continue sanding additional foam on centersection

|

Details

|

|

|

11-08-2016

|

0.50

|

Weights off and beginning to sand foam to shape.

|

Details

|

|

|

11-07-2016

|

0.50

|

Sand edges of centersection spar to final shape.

|

Details

|

|

|

11-07-2016

|

1.00

|

Epoxy additional foam to forward center area of ce

|

Details

|

|

|

11-06-2016

|

1.25

|

Excess fiberglass removed and spar pried out of ji

|

Details

|

|

|

11-06-2016

|

0.50

|

All weights and clamps off and peel-ply removed

|

Details

|

|

|

11-05-2016

|

0.50

|

After last evening, clean up only today. 27 epoxy

|

Details

|

|

|

11-04-2016

|

3.50

|

Lay in 6 layers UNI into centersection spar jig

|

Details

|

|

|

11-04-2016

|

1.50

|

Add in all internal spar components, clamp and wei

|

Details

|

|

|

11-03-2016

|

0.75

|

Wood blocks ready with clamps for tomorrow!

|

Details

|

|

|

11-03-2016

|

3.50

|

Epoxy Hot Box ready for tomorrow! Nice toasty 95

|

Details

|

|

|

11-02-2016

|

0.01

|

Ready for Fiberglass!!

|

Details

|

|

|

11-02-2016

|

1.00

|

Line Centersection Spar Jig with Contact Paper

|

Details

|

|

|

11-02-2016

|

1.00

|

Edge Centersection Spar Jig with Packaging Tape

|

Details

|

|

|

10-31-2016

|

0.75

|

Mark Outline Position of all Centersection Interna

|

Details

|

|

|

10-31-2016

|

0.50

|

Final Fitting of Internal Centersection Spar Parts

|

Details

|

|

|

10-31-2016

|

0.40

|

Add Temporary Alignment Nails for DWA-5 Positionin

|

Details

|

|

|

10-20-2016

|

0.75

|

Final adjustment of DWA-5's

|

Details

|

|

|

10-19-2016

|

1.00

|

Begin to dry-fit all Centersection Spar internal p

|

Details

|

|

|

10-18-2016

|

1.50

|

Cut 18 pieces of UNI fiberglass for Centersection

|

Details

|

|

|

10-10-2016

|

0.25

|

Clean up/Finish DWA-5's

|

Details

|

|

|

10-08-2016

|

1.50

|

Trim DWA-5 Hardpoints and Epoxy into DWA-5's

|

Details

|

|

|

10-07-2016

|

2.00

|

Trim DWA-5's to shape

|

Details

|

|

|

10-06-2016

|

0.50

|

Test fit and set Final Alignment of DWA-4 & DWA-8

|

Details

|

|

|

10-05-2016

|

0.50

|

Sand and Clean Up DWA-4 & DWA-8

|

Details

|

|

|

10-04-2016

|

1.00

|

Wet Flox WA-1's into DWA-4 and DWA-8

|

Details

|

|

|

10-03-2016

|

1.50

|

Final shape all foam for main wing spar

|

Details

|

|

|

10-02-2016

|

2.25

|

Begin cutting foam for main wing spar

|

Details

|

|

|

09-30-2016

|

1.00

|

Finish main wing spar foam templates

|

Details

|

|

|

09-29-2016

|

1.25

|

Cut templates for main wing spar foam inserts.

|

Details

|

|

|

09-28-2016

|

1.50

|

Finish alignment lines on main spar jig.

|

Details

|

|

|

09-27-2016

|

2.50

|

Layout alignment lines on main spar jig

|

Details

|

|

|

09-26-2016

|

2.00

|

Lay up 1/4" fibreglass for WA-5 hardpoints

|

Details

|

|

|

07-29-2016

|

2.75

|

Construct Bulkhead FS-180

|

Details

|

|

|

07-22-2016

|

3.75

|

Construct Bulkhead 153

|

Details

|

|

|

06-18-2016

|

4.75

|

Construct bulkhead 144.5

|

Details

|

|

|

05-27-2016

|

3.25

|

Construct Front Seat Bulkhead

|

Details

|

|

|

05-07-2016

|

5.50

|

Construct Bulkhead FS 73

|

Details

|

|

|

04-16-2016

|

5.00

|

Construct Bulkhead FS 57

|

Details

|

|

|

03-05-2016

|

4.00

|

Construct Bulkhead FS-47

|

Details

|

|

|

11-14-2015

|

3.00

|

Final shape DWA 4 & 8

|

Details

|

|

|

10-30-2015

|

3.00

|

Cut plywood and bend to form DWA-4 & 8

|

Details

|

|

|

10-04-2014

|

14.00

|

Finish Main Spar Jig

|

|

|

|

05-19-2007

|

0.50

|

Test epoxy mix

|

Details

|

|

|

05-19-2007

|

0.50

|

Add one set of legs to fiberglass cabinet

|

Details

|

|

|

05-18-2007

|

0.75

|

Clean, Charge, and Recalibrate Epoxy Pump

|

Details

|

|

|

05-16-2007

|

0.50

|

Calibrate Epoxy Pump

|

Details

|

|

|

05-15-2007

|

10.00

|

Finish building benches

|

Details

|

|

|

05-08-2007

|

5.00

|

Build fiberglass cabinet support

|

Details

|

|

|

01-07-2007

|

1.00

|

Prime and paint folding cutting table sections

|

Details

|

|

|

01-06-2007

|

2.00

|

Build folding cutting table sections

|

Details

|

|

|

01-05-2007

|

2.00

|

Finish cutting wood for fiberglass cabinet and tem

|

Details

|

|

|

01-05-2007

|

2.50

|

Build one 4' bench and start folding table constru

|

Details

|

|

|

01-04-2007

|

2.50

|

Cut wood for templates and fiberglass cabinet

|

Details

|

|

|

01-03-2007

|

1.50

|

Assemble Bench Legs

|

Details

|

|

|

01-01-2007

|

2.50

|

Cut wood for benches

|

Details

|

|